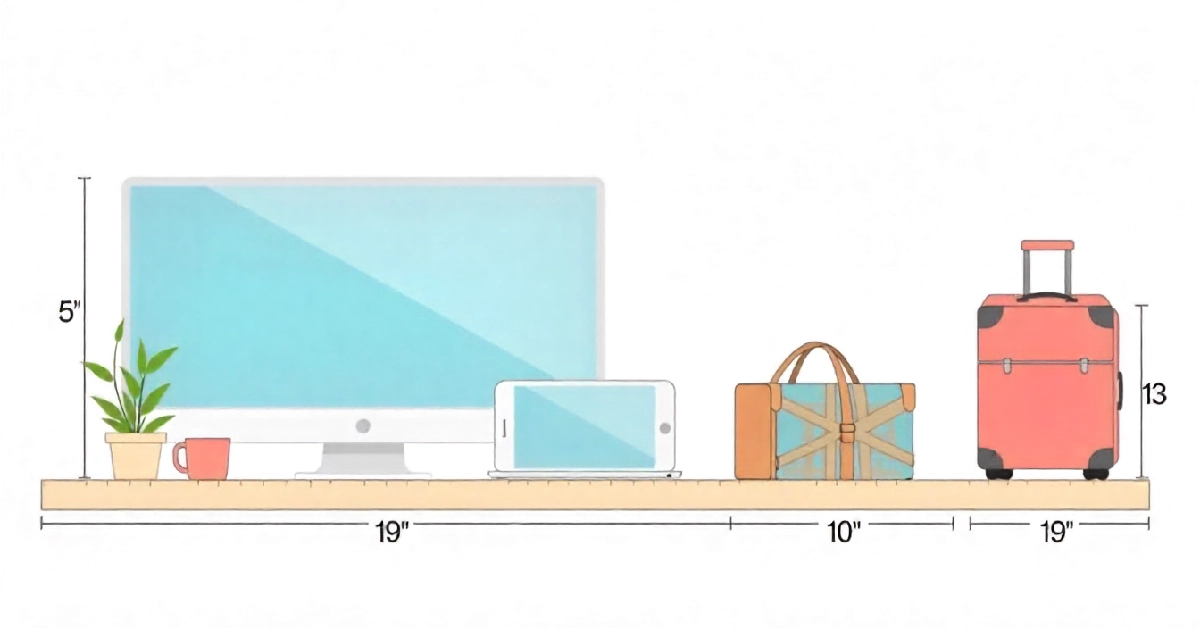

19 inches is a measurement that’s about 48.26 centimeters long or roughly 1.58 feet. You can picture it as a bit longer than a foot and a half, making it easy to spot in daily life. Think of common items like a small suitcase or a computer screen to get a feel for this size. This guide breaks down conversions, comparisons, and tips to help you understand and use this length measurement effectively.

Converting 19 Inches to Other Units

19 inches equals 48.26 centimeters in the metric system. In feet, it’s 1 foot and 7 inches, or about 1.58 feet total. You can also think of it as 0.4826 meters for larger scales.

Converting measurements helps when you shop online or work on projects. For example, if a product lists sizes in centimeters, knowing 19 inches is 48.26 cm avoids mistakes. People often use apps or calculators for quick changes. This keeps things simple and accurate. Always double-check units to match what you need.

In imperial units, 19 inches is part of the system used in the US. It comes from older standards but stays popular today. Synonyms like “nineteen inches” or “19 in” mean the same thing. These terms pop up in hardware stores or recipes.

Everyday Objects That Are About 19 Inches Long

Many household items measure around 19 inches to give you a quick reference. A standard carry-on suitcase often stands 19 inches tall. Computer monitors are commonly 19 inches across the diagonal.

Visualize a roll of paper towels laid out flat—it’s close to 19 inches end to end. Or consider a large pizza box, which can be about 19 inches wide. These common attributes make it easy to spot this size without tools. Backpacks for school kids might hit this length too. Junior baseball bats are another example, fitting young players perfectly.

Bed pillows typically stretch 19 to 20 inches long, offering a soft comparison. Small coffee tables may have a width of 19 inches, ideal for tight spaces. Collocations such as “19-inch monitor” or “19-inch suitcase” show up in stores often. They help buyers pick the right fit.

How to Visualize 19 Inches Without a Ruler

You can use body parts or paper to estimate 19 inches easily. An average adult forearm from elbow to wrist is about 15 to 18 inches—add a hand width for the rest. Stack three dollar bills end to end since each is 6.14 inches long.

Try folding a standard letter-sized paper, which is 11 inches long, and imagine almost two of them. Your shoe might be 10 to 12 inches, so think of one and a half shoes. This method works well for quick checks. Practice with known items to get better at guessing.

Hyponyms like “diagonal length” apply to screens measuring 19 inches. Or use “height” for suitcases at this size. These specifics refine your estimates. Antonyms such as “short distance” contrast with longer ones, but 19 inches feels medium.

Common Uses for 19-Inch Measurements

19 inches shows up in tech, travel, and home goods often. Laptop screens or monitors use this size for compact setups. Suitcases meet airline rules at 19 inches high.

In kitchens, serving platters reach 19 inches for big meals. Furniture like side tables might have 19-inch widths. This size balances portability and function. Builders use it for shelves or frames too. It fits many standard designs.

Hypernyms include “imperial unit” for inches in general. 19 inches falls under this broader category. Meronyms refer to parts, like how 19 inches breaks into 19 one-inch segments. These terms highlight structure.

Comparing 19 Inches to Body Parts

Compare 19 inches to an arm span from fingertip to elbow, around 18 to 20 inches for adults. A man’s footstep averages 30 inches, so 19 is about two-thirds of that. Women’s footsteps are closer to 23 inches, making 19 a bit shorter.

Your lower leg from knee to ankle might measure 15 to 19 inches. This gives a personal way to gauge. Kids’ heights grow past this quickly. Use these semantically related entities like “arm length” or “foot size” for relatable checks.

Hands span 7 to 9 inches open, so two and a half hands equal 19 inches. Practice this for shopping or crafts. It builds confidence in estimates.

Fun Facts and History About the Inch

The inch comes from the Latin word “uncia,” meaning one-twelfth. It started as the width of a thumb in old times. By 1959, it officially became 2.54 centimeters exact.

Etymology traces “inch” back to Roman measurements. Today, it’s used worldwide despite metric systems. 19 inches has no special history but appears in standards like wheel rims. Polysemy means “inch” can also be a verb, like inching forward slowly.

In the 1800s, measurements varied by country. Now, they’re uniform. This evolution makes conversions reliable.

How Long Is 19 Inches in Different Contexts

In sports, a junior bat might be 19 inches for young kids. Hair extensions at 19 inches fall to mid-back. These contexts change how we see the length.

For cars, 19-inch rims are popular for style and performance. In art, canvases at this size suit small projects. Connotations of “compact size” fit 19 inches well. It’s not too big or small.

Holonyms place 19 inches within larger systems, like a yard (36 inches). This shows relations.

FAQs About 19 Inches

How do I convert 19 inches to cm? Multiply by 2.54 to get 48.26 cm.

Is 19 inches the same as 1.5 feet? No, it’s 1.583 feet exactly.

What objects are exactly 19 inches? Some monitors and suitcases hit this mark.

Can I measure 19 inches with paper? Yes, use about 1.7 sheets of letter paper.

Rare attributes include using 19 inches for specific tools like levels. Lexical terms like “dimension” describe it broadly.

To wrap up, understanding how long 19 inches is simplifies many tasks. From conversions to comparisons, you’ve got the tools now. Next time you see a 19-inch item, you’ll know just what it means. Keep practicing these tips for better accuracy.